Dynamic Excellence in Electron & Ion Beam Technology and Engineering

D.I.S-cover our Expertise

D.I.S Germany GmbH employs experts with many years of experience in physics, mechanical and system engineering, as well as high-precision manufacturing. With this extensive expertise, we focus on delivering cutting-edge solutions in two key areas: vacuum technology and ion beam technology. Through continuous collaboration with our partners in the United States, we ensure that our solutions are at the forefront of innovation and precision.

On the following pages, you will find detailed information, tutorials, recommended publications, and other content related to these technologies. These resources provide you with insights into the scientific principles behind vacuum and ion beam technology:

While our main expertise is concentrated on vacuum and ion beam technologies, our internal knowledge extends across a broader range of related fields. We leverage this comprehensive understanding to provide our clients with highly specialized solutions and expert guidance tailored to their specific needs.

At D.I.S Germany GmbH, we are committed to sharing our expertise to empower our customers with the tools, information and insights necessary to solve complex challenges and achieve optimal results in their projects.

Vacuum Technology

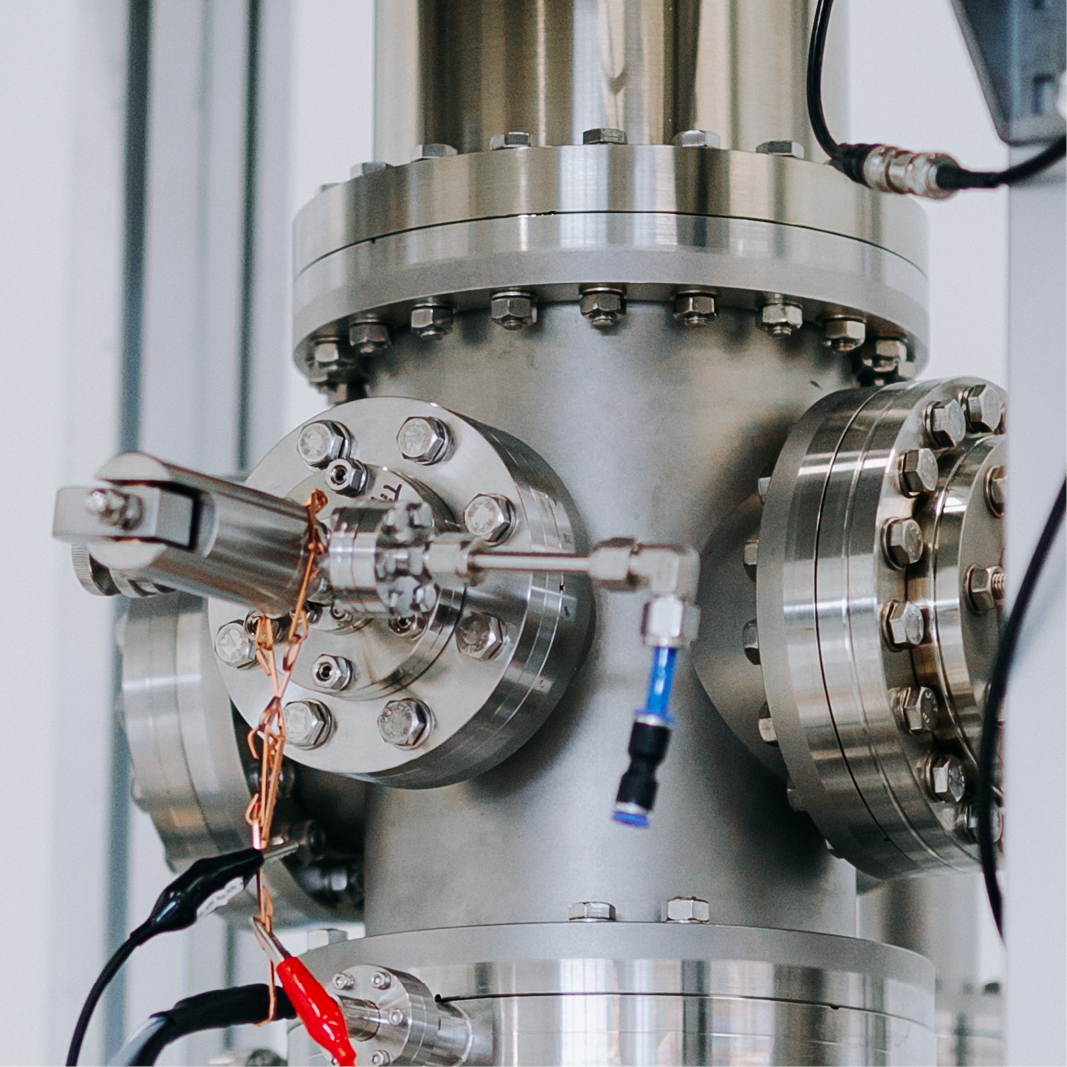

A mandatory precondition of electron and ion beam technology-related components, assemblies and complete facilities is the generation, maintaining and monitoring of vacuum. These systems are a cornerstone in various industrial, research, and scientific applications. The concept of vacuum technology dates to 1657, when Otto von Guericke demonstrated the power of vacuum with his famous Magdeburg hemispheres. This groundbreaking experiment highlighted the significant potential of evacuated environments, laying the foundation for further advancements in vacuum systems.

Today, vacuum systems are integral to many sectors, including:

- Industrial Applications

- Scientific Research

- Electron and Ion Beam Technology

Vacuum Qualities

In common parlance the term vacuum describes the absence of matter in a defined volume, however, a space completely devoid of matter has not been discovered or generated yet. For many technical applications and the corresponding calculations and simulations, it is sufficient to assume a perfect vacuum.

In electron and ion beam technology such assumptions would lead to great deviations and a grading of vacuum qualities becomes necessary. For this purpose, the absolute pressure is used. The following table shows the corresponding classification according to ISO 3529-1:2019. Vacuum Quality Classification (ISO 3529-1:2019)

| Vacuum Quality | absolute Pressure [mbar] | Particle Density [cm⁻³] |

|---|---|---|

| atmospheric pressure | 1013,25 | 2,65 · 10¹⁹ |

| low (rough) vacuum | 1013,25 -10⁰ | 2,65 · 10¹⁹ – 2,65 · 10¹⁶ |

| medium (fine) vacuum | 10⁰ – 10⁻³ | 2,65 · 10¹⁶ – 2,65 · 10¹³ |

| high vacuum | 10⁻³ – 10⁻⁸ | 2,65 · 10¹³ – 2,65 · 10⁸ |

| ultra-high vacuum | 10⁻⁸ – 10⁻¹¹ | 2,65 · 10⁸ – 2,65 · 10⁵ |

| extreme-high vacuum | < 10⁻¹¹ | < 2,65 · 10⁵ |

Irradiation facilities must generally be operated in high or ultra-high vacuum conditions.

Another important parameter connected to the quality of a vacuum is the mean free path (MFP), which describes the average distance travelled by particles without a collision between each other.

If residual gas pressure is mentioned, it generally refers to the composition of the air. The following table provides an overview of the gas composition of the air at 20 °C and 50 % humidity.

| Gas Type | Partial Pressure [mbar] |

|---|---|

| nitrogen | 781,8 |

| oxygen | 209,7 |

| water vapour | 12 |

| argon | 9,34 |

| carbon dioxide | 3,3 · 10⁻¹ |

| neon | 1,82 · 10⁻² |

| helium | 5,23 · 10⁻³ |

| krypton | 1,15 · 10⁻³ |

| hydrogen | 4,94 · 10⁻³ |

| xenon | 8,7 · 10⁻⁵ |

Vaccum-Suitable Materials

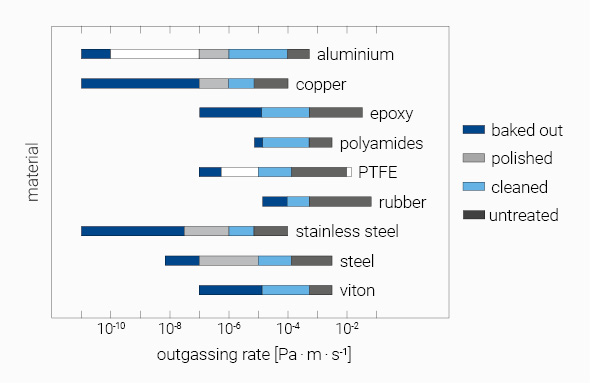

Components of a vacuum facility must only be made of materials that meet special requirements. One of the most important properties are gas tightness and a low inherent vapour pressure. Otherwise, strong outgassing would occur as soon as the material is exposed to vacuum conditions, which in turn would lead to a contaminated vacuum. Figure 1 illustrates the outgassing rates of different materials after different treatment or process stages.

For that reason mostly stainless steel is used for vacuum exposed components. Aluminium is not as suitable as stainless steel, but has the advantage of a lower density, resulting in a lower mass for the desired component. Copper and viton are generally used for seals and boron nitride or aluminium oxide for insulation purposes.

Materials that should be avoided by all means are rubber, plastics, solder and adhesives. Avoiding these materials often results in increased demands on design and construction.

or process stages.

Working With Vaccuum Facilities

In order to understand a vacuum system fundamentally and design it correctly, a number of factors must be considered.

An important parameter is the vacuum technology design of the system (pumping capacity, system dimensions), which must be taken into account. Furthermore, the flow conditions on the system have to be analysed. A sufficient time interval for outgassing processes of the construction materials should be guaranteed.

The successful operation of vacuum facilities requires high standards and careful handling. The following points touch on the most common sources of error.

- First of all, extreme neatness is of outmost importance. Splinters, other residuals or any kind of grease on the surfaces are not to be tolerated, since this would result in contamination of the vacuum.

- Second, cavities and holes must be avoided because they would act as gas reservoirs and therefore, they reduce pumping efficiency.

- Third, appropriate sealing techniques and materials suited for vacuum conditions need to be applied.

- Finally, as always with complex systems, the error potential is reduced by thinking ahead and careful considerations.

D.I.S – Your reliable Partner in Vacuum Technology

At D.I.S Germany GmbH, we offer expert consulting and deep scientific knowledge in vacuum technology to help you optimize your systems. Get in touch with us today to learn how our expertise can support your next project.

Ion Beam Technology at D.I.S

At D.I.S Germany GmbH, we provide innovative solutions for a wide range of ion beam applications. Our products are designed to support the advancement of research and development, helping to take ion beam technology to the next level.

This page offers an introduction and overview of the physical and technological aspects of ion beam facilities, providing insights into the various components and how they contribute to the success of ion beam applications. Whether you’re looking to enhance your ion beam technology or explore new applications, D.I.S Germany GmbH is your reliable partner in this specialized field.

Tutorials

Charged Particle Beam Diagnostics |

Wien Filter

Wien filters are analytical elements used for separating charged particle beams by velocity using orthogonally superimposed magnetic and electric fields with low weight and compact size compared to other common systems.

Refer to our tutorial for detailed information and the physical background:

Gas Supplies and Analytics | Introduction of Metal Compounds into Ion Sources

The introduction of metal compounds into ion sources often proves to be a challenge. Practical experience has shown that the MIVOC (Metal Ions from Volatile Compounds) method can be used successfully in many cases.

Refer to our tutorial for the physical background and comprehensive information: