SPECIAL FEATURES

- ECRIS with a compact Wien filter for low to intermediate ion beam currents of several hundreds of microamps

- Facility is offered with horizontal ion beam orientation

- vertical ion beam configurations are possible on demand

OPTIONAL SUPPLEMENTING DEVICES

- alternative ion source configurations with Electron Beam Ion Sources (EBIS) for highly charged ions or Field Ionization Sources (FIS) for the ionization of gases and complex molecules

- generation of metal ion beams over a wide range of elements using the MIVOC method (MIVOC: Metal Ions from VOlatile Compounds)

- gas mixing board for different process gases

BASIC CONFIGURATION

The ion irradiation and implantation facility includes an ion beam source with RF and gas feeding systems, ion beam optics, a charge state & mass separator ( Wien filter), an irradiation chamber with substrate manipulator stage (heatable up to 500°C and devices for linear target motion, for the adjustment of the target tilting angle and for target rotation) for substrates up to inch-size, vacuum system, high voltage power supplies and PLC-based command & control (C&C).

Ion Source

The used ion source is an Electron Cyclotron Resonance Ion Source (ECRIS) capable of producing ion beams of hundreds of eμA. Any gas can be fed into the ion source, special techniques can also be used to inject metallic ions and complex organic molecules.

Beam Guiding System

In order to purify the ion beam according to the ion charge state and ion mass a compact Wien filter (low or intermediate ion beam current applications) is mounted downstream of the extraction system.

ION IRRADIATION CHAMBER

The ion irradiation chamber includes a Faraday cup and a manipulator stage suitable for heating (up to 500°C or higher on customer demand) and rotation of the substrates. The manipulator stage is installed on a linear and rotary feedthrough for linear translation as well as for realizing different ion implantation angles.

TECHNICAL DATA

| produced ions |

- protons (H+), noble gas ions (e.g. He+, Ne+, Ar+, Xe+ etc.) but also other elements,

- injection methods for metallic ions offered on request

|

| energy range |

from 1 keV to 50 keV |

| ion beam current |

hundreds of eμA |

| charge state & mass filter |

|

| beam guiding system |

electrostatic beam optics with appropriate HV power supplies |

| beam scan |

samples with variable sizes up to 25 mm or on request |

| vacuum |

- base pressure down to ~10-8 mbar,

- working pressure ~10-6 mbar and higher

|

| software |

- Programmable Logic Controller (PLC) and graphical Human Machine Interface,

- full control of ion source and beam parameters,

- optional, full control of the parameters of the irradiation chamber

|

| irradiation chamber |

- for 25 mm sample size and larger (on customer demand)

- variable implantation angle,

- heating up to 500°C and higher (on customer demand),

- measurement of the beam current,

- software control of the applied ion current,

- transfer system on request

|

| approx. box size (length x width x height) |

2 m x 1 m x 2 m |

The facility has a modular design and is offered as a complete ion irradiation solution. Additionally, the individual components of the system can be ordered.

Please do not hesitate to contact us to find a solution suitable for your specific application.

Datasheet:

Available soon.

RELATED PRODUCT VIDEOS:

Animation showing the facility with all its labeled components:

Type-M-Facility_orbit_labeled.mp4

Following the path of the ions through the facility:

Type-M-Facility_cut_particle_tracing.mp4

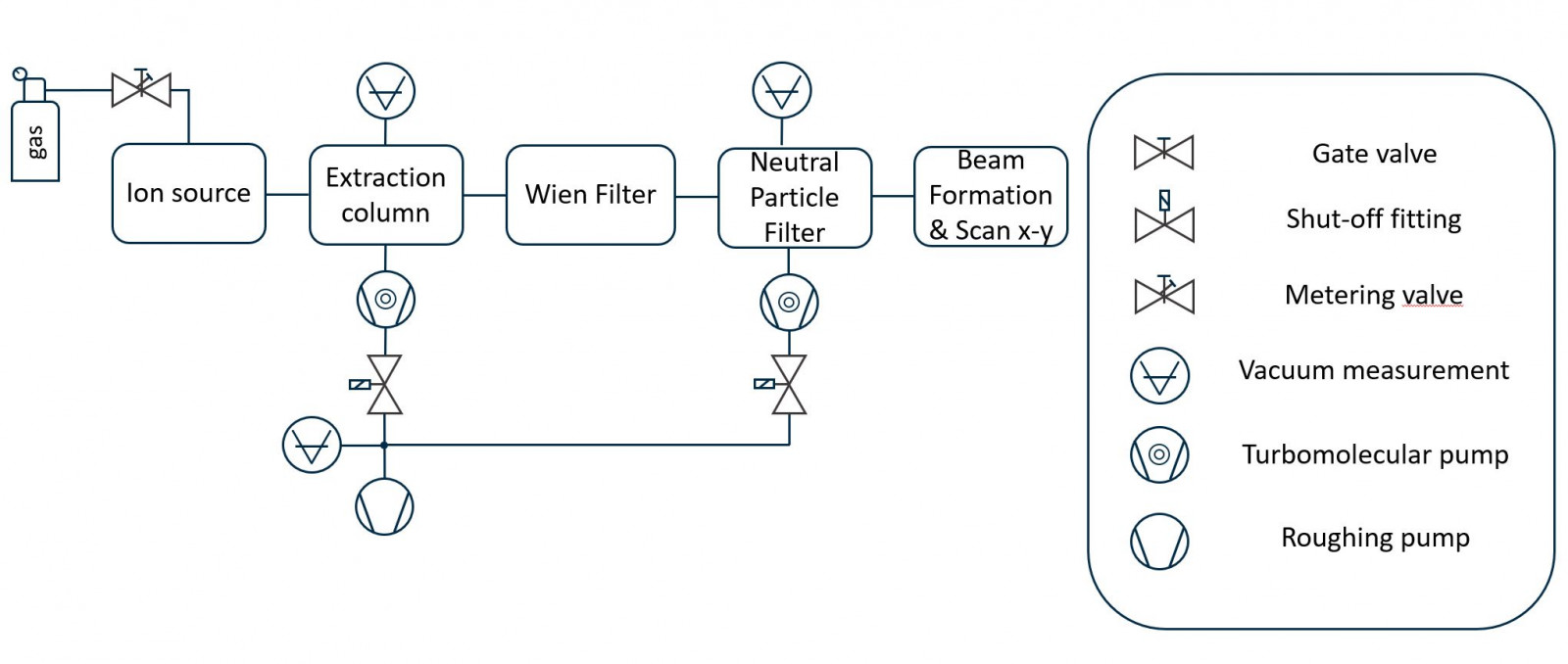

Figure 1: Vacuum scheme of the D.I.S ion irradiation and implanter setup Type-M without irradiation chamber.

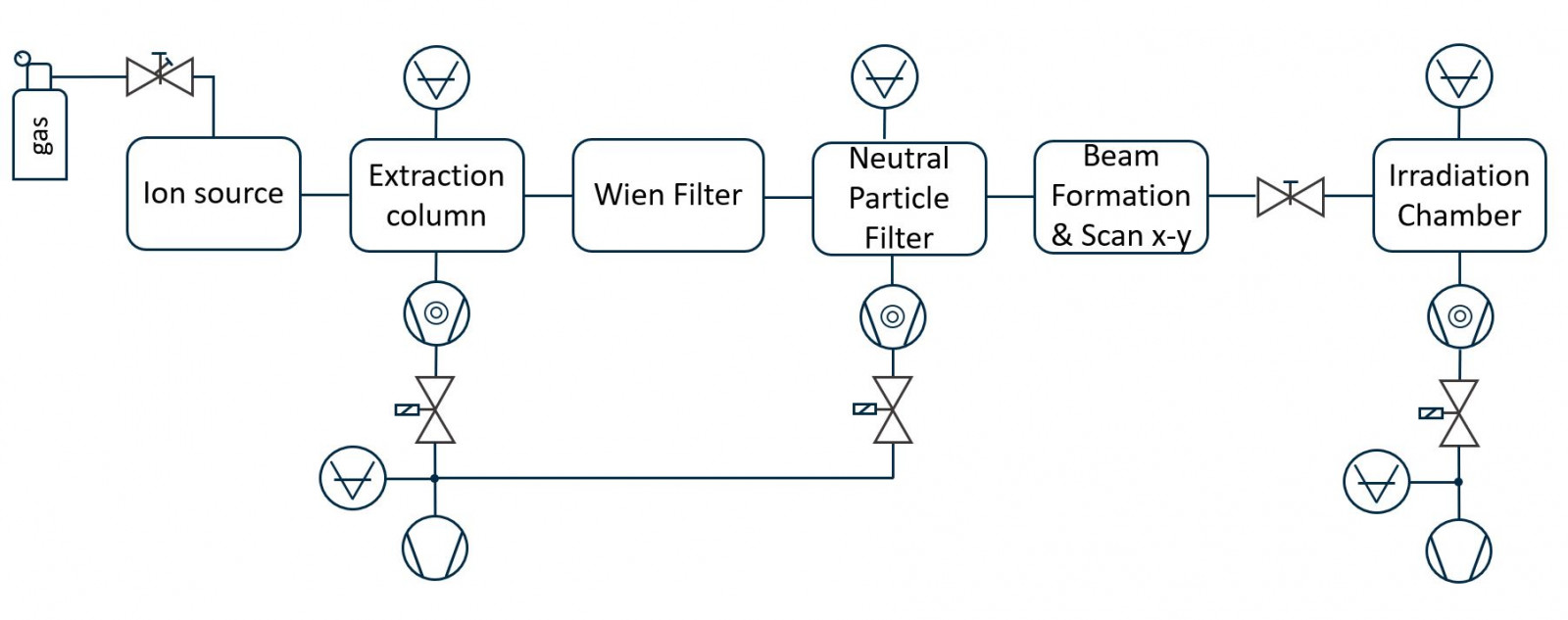

Figure 1: Vacuum scheme of the D.I.S ion irradiation and implanter setup Type-M without irradiation chamber. Figure 2: Vacuum scheme of the D.I.S ion irradiation and implanter setup Type-M with irradiation chamber.

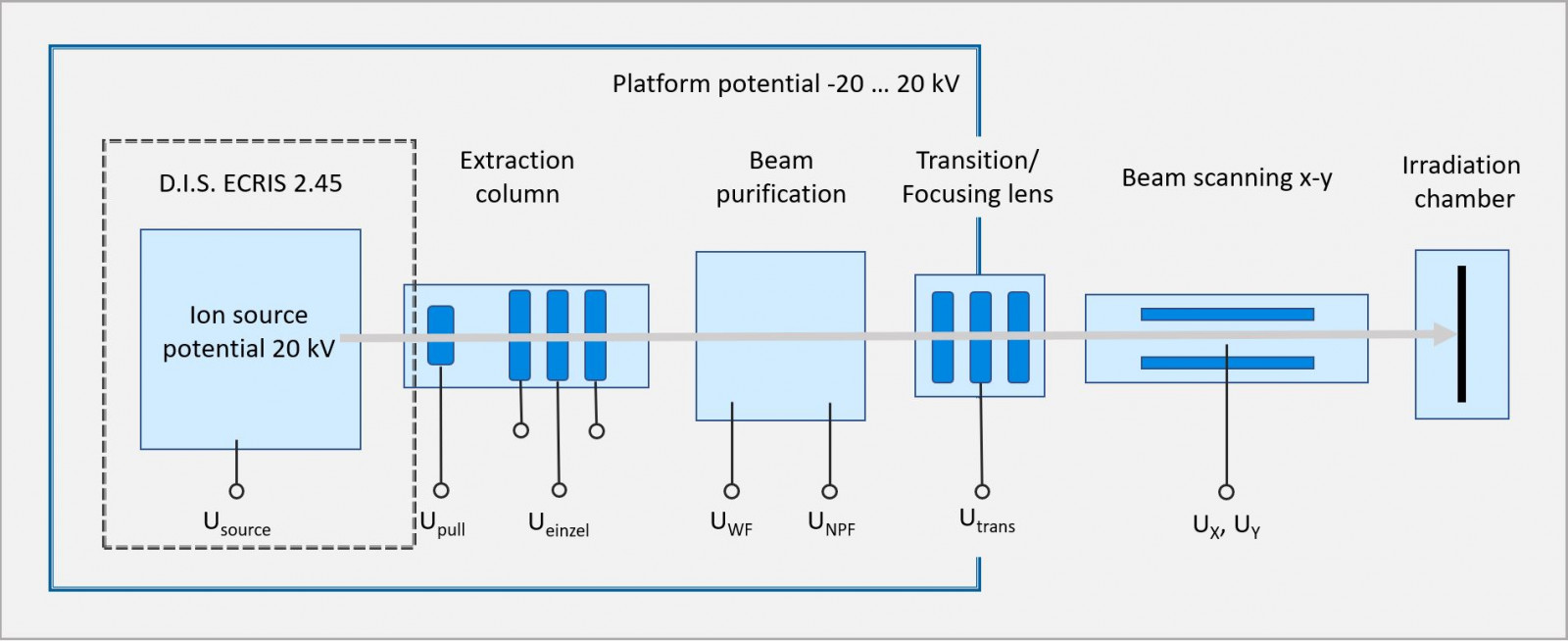

Figure 2: Vacuum scheme of the D.I.S ion irradiation and implanter setup Type-M with irradiation chamber. Figure 3: Potential scheme of the D.I.S ion irradiation Type-M setup including irradiation chamber

Figure 3: Potential scheme of the D.I.S ion irradiation Type-M setup including irradiation chamber