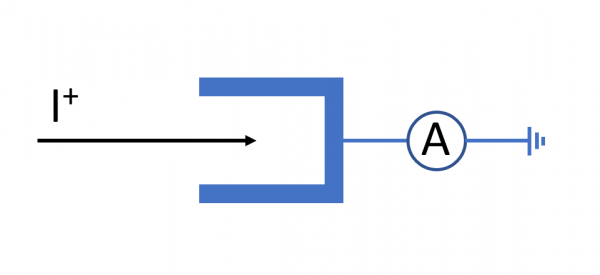

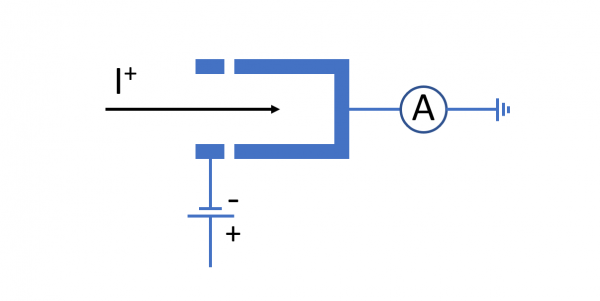

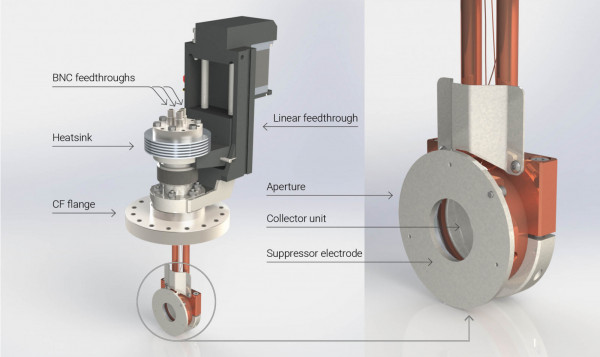

Faraday cups are used for measuring the electrical current of a charged particle beams in real time and independent of the pressure. Our systems are suitable down to ultra-high vacuum conditions. They can be used for measuring the electrical current of an electron or ion beam in the range of fA and pA up to mA and are suitable for beam power loads of up to 200 W and beyond. A suppressor electrode is built in by standard for compensating the secondary electron emission, increasing the measurement precision in the process.

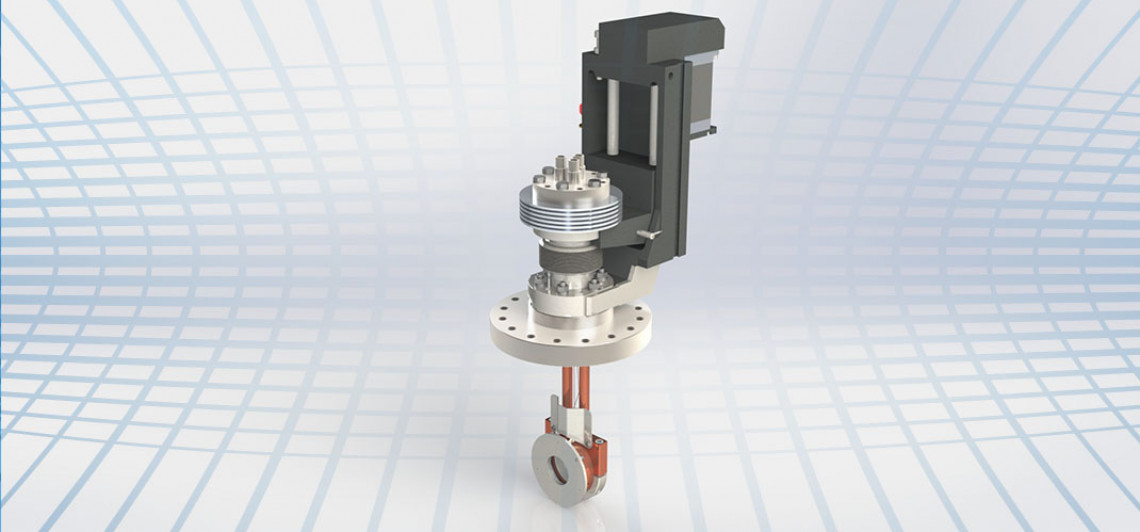

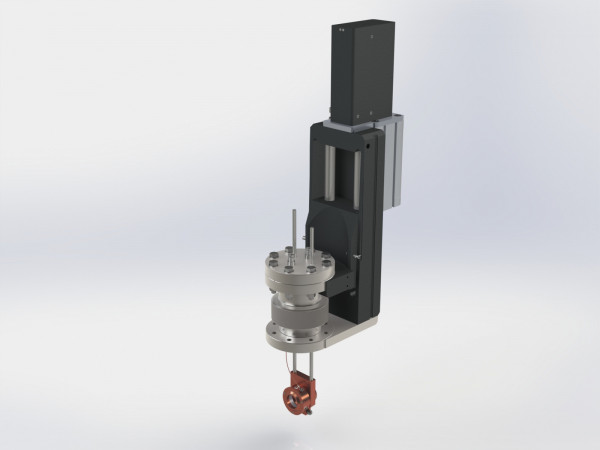

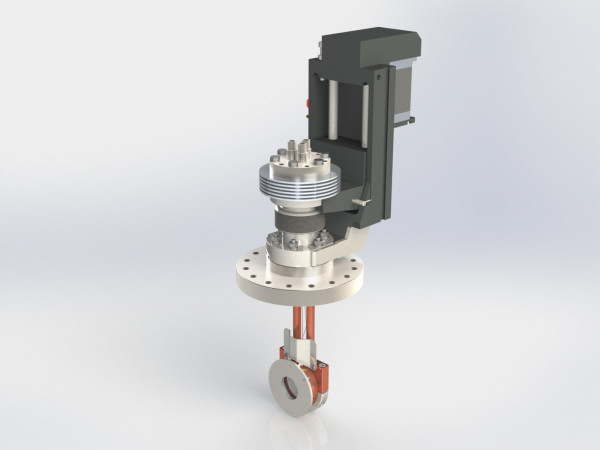

Faraday Cup, CF63, passive cooled, inline 931-S7-09-00006

Special Features:

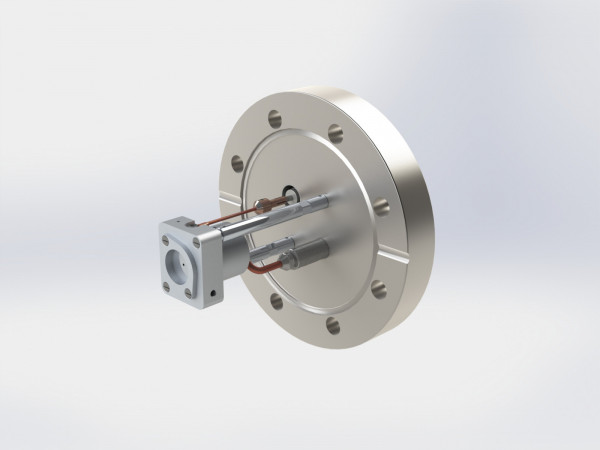

- fixed inline installation

- CF63 base flange

- exchangeable apertures with diameters ranging from0.5mm

up to 5mm - triaxial wiring and feedthrough for the Faraday cup detector

for low noise measurements - passive cooling for power loads up to 3W

Optional Supplementing Devices:

- power supply for the suppressor voltage

- current measurement device for beam currents of fA up

to mA - additional apertures